Jump To:

February 18, 2026

The Raleigh Skyline has one less tower crane. Last week, the contractor disassembled the tower crane at the new City Hall. Taking down the tower crane is a complex process that takes multiple days to complete. The crew uses a mobile crane and climbing crews to dismantle the tower crane.

The removal of the tower crane is a major milestone for the new City Hall and marks the completion of the building's outer shell. Now, crews turn their attention to the building's interior work.

February 3, 2026

Big news, the tower crane is coming down.

What does this mean for you?

Hargett Street will be closed Feb. 11-15 between Dawson Street and McDowell Street to allow crews to remove the tower crane. The street must be closed for this work for safety reasons. The back exit of RMB will also be closed during this work.

Why is it coming down?

The removal of the tower crane is a significant milestone for the City Hall project. The crane's removal indicates that the dry-in stage of the project is near. Dry-in is the point in the construction process at which the rough exterior work is complete. This means the building is essentially waterproof at this point, and crews will now be working on the interior.

Can you believe it? This project is on the home stretch. Substantial completion is scheduled for December of this year.

December 14, 2025

Construction has reached the top floor, marking a significant milestone. Now, the contractor is focusing on completing the exterior shell of the building and framing and finishing the interior.

November was another busy month at City Hall, and crews continue to make significant progress.

Here is a list of some of the work crews have performed in the last month.

- The last beam was set, and the topping out party was on Nov. 7.

- Crews have framed in the tower floors up to level 13.

- The elevator steel is installed up to level 15.

- Both internal stairs are complete.

- The penthouse steel is being installed.

- Precast installation continues.

- Interior caulking of windows is ongoing.

- Installation of and caulking of the glass on levels one through three continues.

- The terrace planter walls on level two were poured.

- Installation of elevators nine and ten is ongoing.

- Drywall installation on levels one and two has begun.

October 29, 2025

The City Hall construction team has some BIG news!

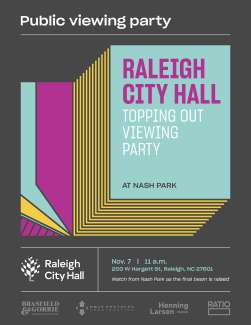

The tower crane will place the building's top beam on Friday, Nov. 7! This is called topping out.

Want to watch this exciting project milestone? Head to Nash Square on Friday, Nov. 7, at 10:45 a.m. to watch the topmost beam of our new City Hall be lifted and placed atop the building.

What is topping-out?

Topping-out is a big deal for the construction team, as it signifies the end of the vertical stage of the construction. To celebrate this milestone, a tree is placed on the topmost iron beam, often with flags and streamers tied to it. The celebration is traced to the ancient Scandinavian tradition of placing a tree atop a new building to appease the tree-dwelling spirits. After the beam is placed, there is a celebration for the construction workers who are usually treated to a meal.

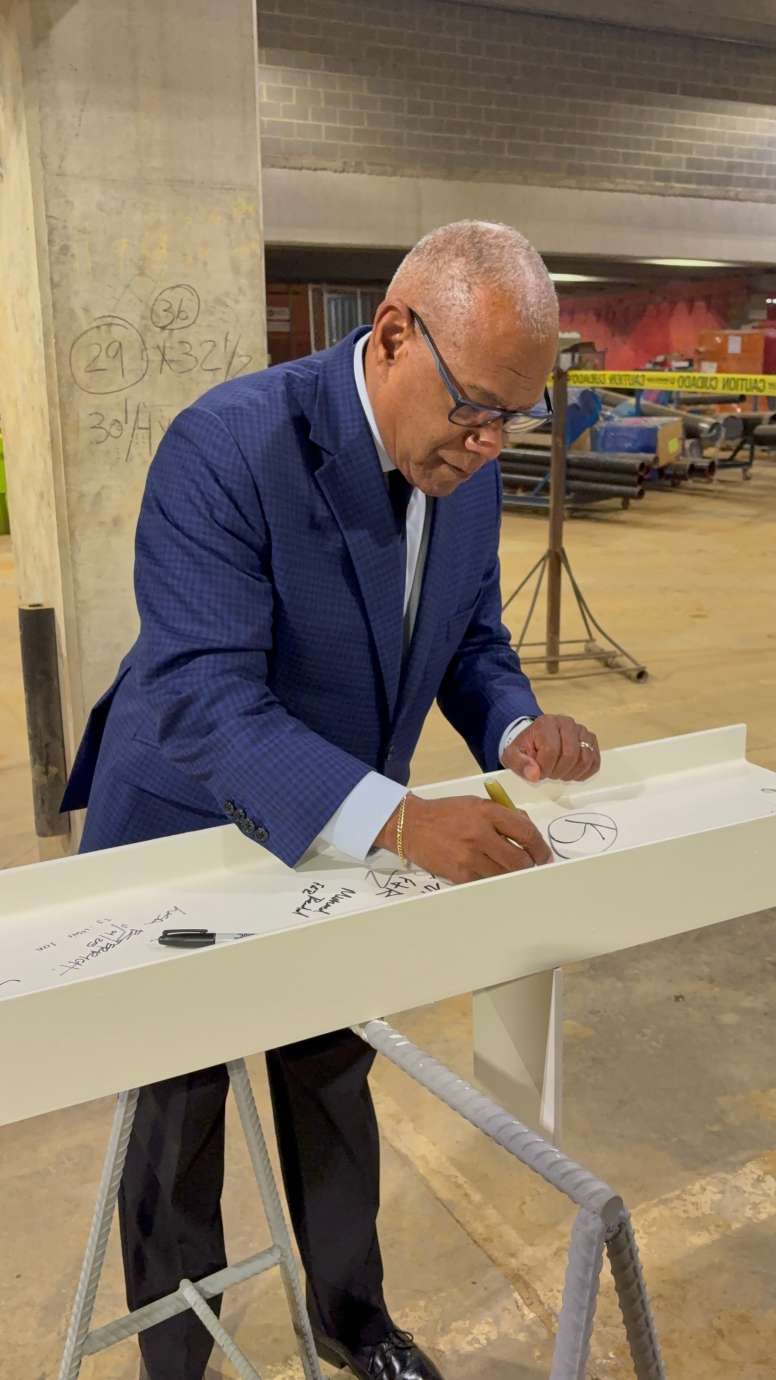

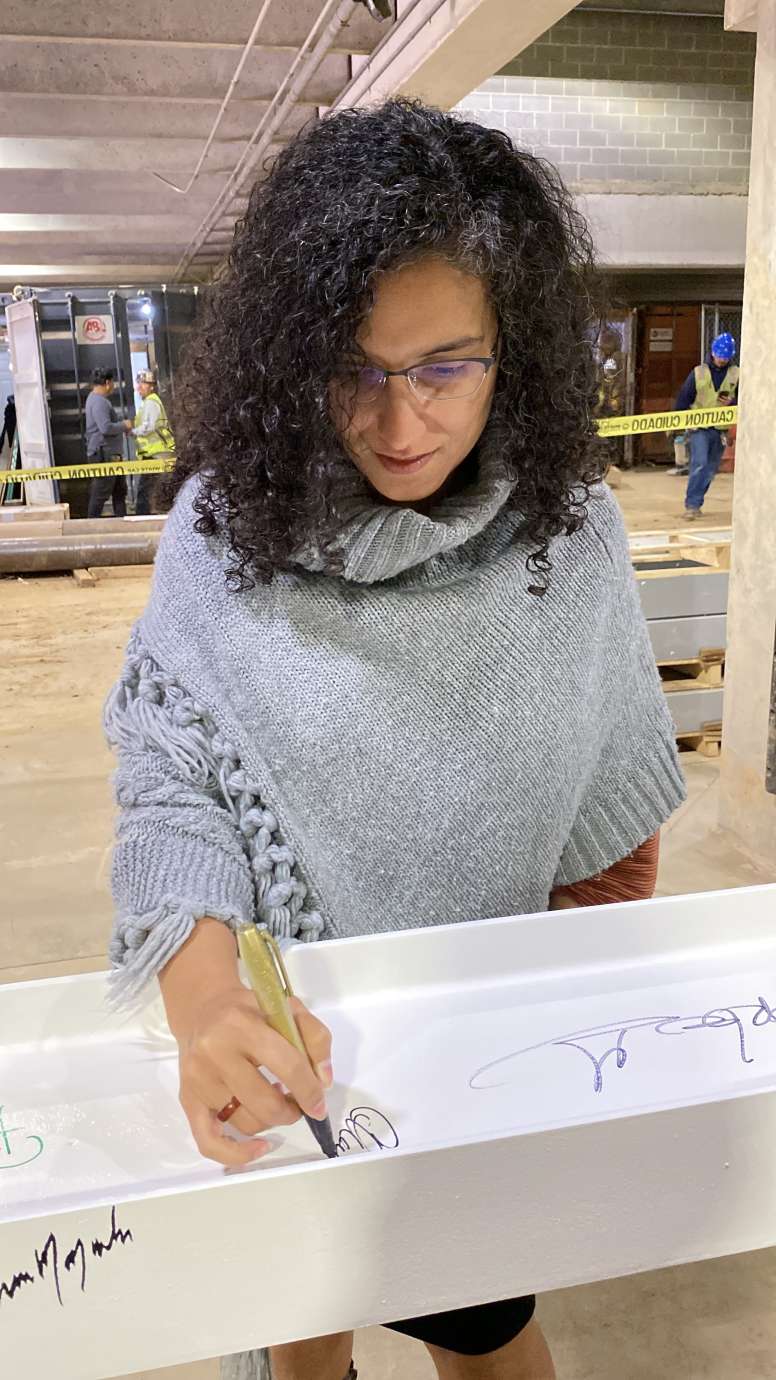

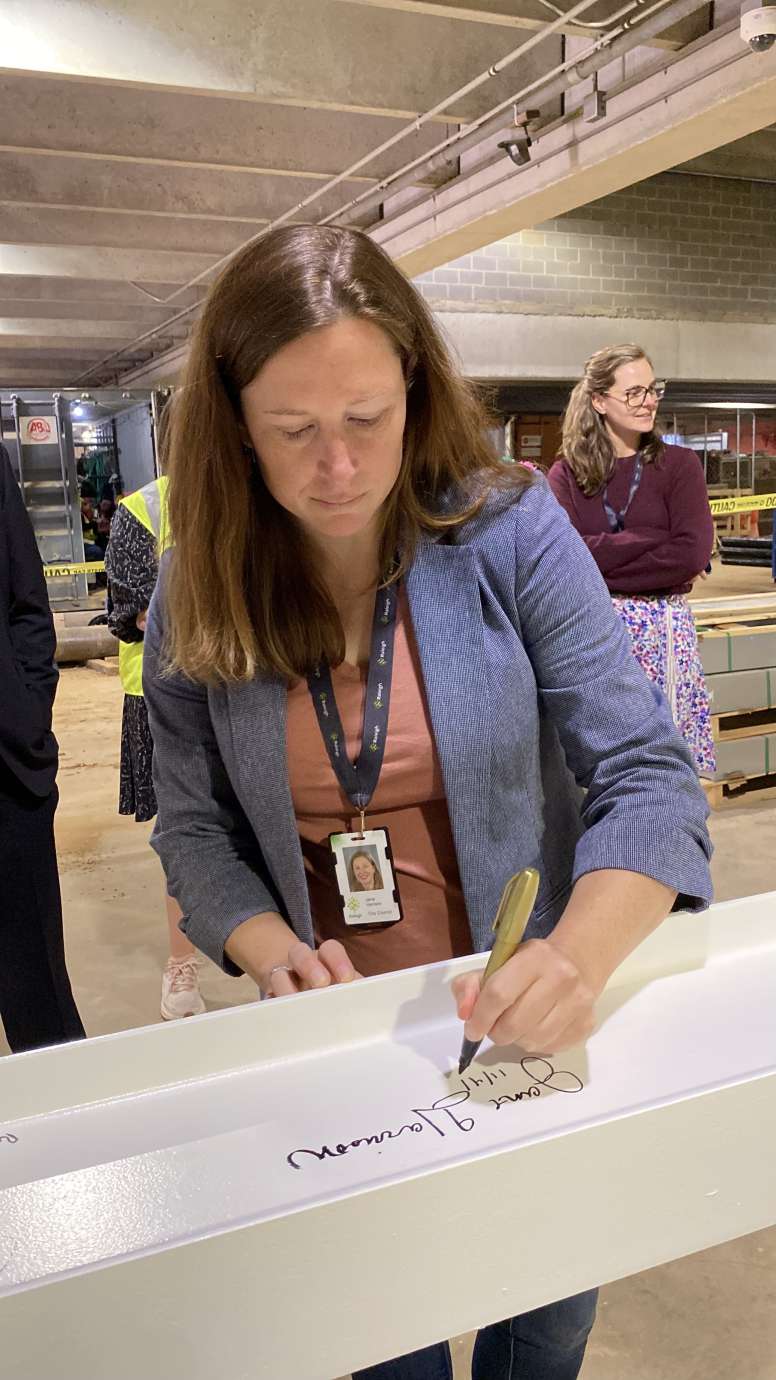

The topping-out celebration remains a common practice worldwide. In the United States, the last beam of a high-rise building is often painted white and signed by the workers.

October 22, 2025

Check out this rendering of the City Hall veranda. Once we are in the new building, I will be eating lunch outside as much as possible. How about you?

And now for the City Hall update.

It has been a very busy couple of weeks at City Hall. A team installed the new generators. They are massive. On Sunday, Oct. 5, crews delivered the two natural gas generators to their new home.

If you have seen the building in the last few weeks, you may have noticed the windows going in on the first and second floors. Wow, they really look fantastic.

September 18, 2025

And it’s the stairway to council chambers.

Crews are working on what the team calls the monumental stairs. Monumental meaning epic or grand. These stairs will be a prominent feature as you enter City Hall and will lead to the second floor and the city council chambers. The public art, a light installation, will be suspended from the ceiling of the two-story lobby and up the grand staircase, creating an inspiring scene.

September 4, 2025

Is that glass in the windows? Yes, it is!

Crews continue to install the precast outer shell, and the contractor has reached the twelfth floor. Wow, the team has completed so much work in the past 30 days.

Let’s review what the team accomplished in August.

- Crews are working on level 13

- Teams are working on interior framing on levels six through eight.

- The nighttime crew is installing the precast outer shell of the building.

- A crew finished the elevator steel for levels six and seven.

- The two staircases are coming along; one is up to level nine and the other is up to level six.

- A crew is working on the main stairs to the Council chambers.

- Crews completed the air barrier and waterproofing through Level four.

- The Buck Hoist install is complete, and it is in operation.

- Teams are installing glass knife plates to hold the large glass panels on the lower levels of the building.

What will the team do in September?

- Crews aim to have both the 13 and 14 floors done.

- The interior stairs are scheduled to reach the eighth floor.

- Crews should complete the framing of the interiors of levels six and seven.

- The night crew will continue installing the precast outer shell and window glass.

- A crew will install the glass at the main entrance.

Things are really coming together, and we have several significant milestones on the horizon this month.

August 20, 2025

Crews are working around the clock on the new City Hall and making some excellent progress. Just about every night, a crew is on-site placing the precast outer shell of the building. Just recently, they started installing the tower sections. Check out the size of those windows.

During the daytime hours, the contractor has crews working on adding the levels to the building and framing the inside of the building. There is also a team working on installing fiber conduit and preparing for the installation of the generator that will be used as backup power for the new building.

August 5, 2025

Wow, we sure are moving on up!

Crews just finished the tenth floor! Seems like only yesterday we were setting up the tower crane, and now we only have seven more floors to go.

Here is a recap of what the construction team has completed in July:

- Crews completed the concrete slab and columns for levels eight, nine, and ten.

- Teams are working on the internal framing of floors one through 5. That work includes tasks such as building out the walls and installing ductwork, electrical conduit, and even the placement of electric boxes and IT connections.

- Brise Soleil steel was installed on all four terraces. Yes, the new building will have four terraces. Talk about a great spot for lunch.

- A crew has completed the install of the elevator steel from level one to level six, and the building now has but two sets of stairs all the way to level four.

- A team has installed the air barrier and waterproofing up to level four.

- The buck hoist was installed.

- A team has started installing the steel supports that will hold the glass around the entrance to the building.

- And the night crew has installed the precast along the lower levels of the building.

So, what does the team have on the schedule for August?

- They plan to complete the concrete floor and columns on levels eleven and twelve.

- The stairs are on track to be in place up to level 7 on one set and level 9 on the other.

- A team will start building the main stairs up to the Council Chambers.

- The framing team is expected to be completed with their work up to level 5.

- The precast team will install the ribbon precast sections up to the fourth floor.

- The first-floor glass will start going in.

- And a crew will install the new generator pad.

Keep checking back, there will be lots of exciting update to City Hall in the next few months.

July 24, 2025

Good News. Crews completed all work associated with the planned power outage last weekend. The Raleigh Municipal Building had power restored late on Sunday afternoon, and staff were able to return to the building on Monday morning.

Work is progressing. The new building is now 29 percent complete. Not only are crews working on adding new floors, but the teams are also framing out the inside of the building.